Three Decades of Memories -The History of the National Show Glass Commemoratives

Reprinted from "Crown Jewels of the Wire", May 1999, page 19

The Commemorative Originators, Frank and Margaret Miller

(Part II)

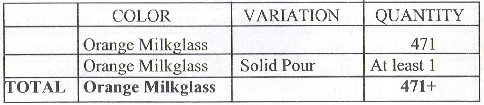

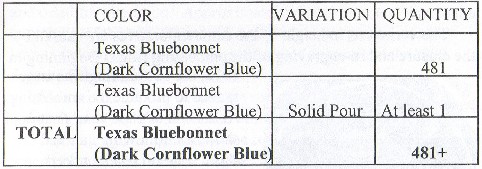

Production Colors

The production colors from 1977 through 1984, 1987, and 1989 through 1999

were all chosen from the tested production colors used by the Mosser Glass

Company. The colors used in 1985 (teal blue), 1986 (lime green with amber

swirls), and 1988 (dark cornflower blue), were specially ordered by the

McDougalds in conjunction with requests by the national show hosts. In each

case, a sample of a known glass product was submitted to Mosser and then sent on

to Coming Glass (New York) for analysis of its composition.

1980 Commemorative Embossing:

11TH NIA CONVENTION

HERKIMER, N.Y. JULY 11-13 1980

1981 Commemorative Embossing:

12TH NIA CONVENTION

SACRAMENTO, CALIF. JULY 10-12 1981

The cost of the 1981 commemorative was $10.00 each.

1982 Commemorative Embossing:

10TH NIA CONVENTION

DENVER, COLORADO JULY 20-22 1979

In 1982 the cost of the commemorative reached $12.00 each.

1983 Commemorative Embossing:

14TH NIA CONVENTION

ROCHESTER, N.Y. JULY 8-10, 1983

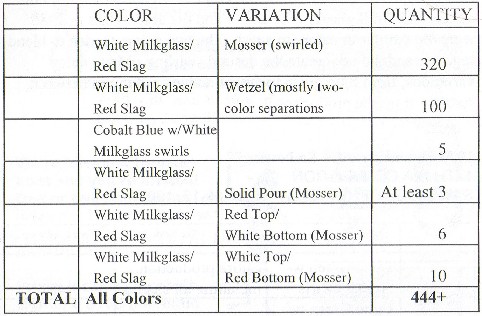

In 1984, the first commemorative in a slag glass was produced using a white

milkglass and a red transparent glass mixture. Mosser Glass Company produced 320

units. When advertised, the insulators sold out immediately, before all the

orders could be filled or insulators held back to take to the national show in

Tacoma. The McDougalds panicked and begged Mosser to run another 100 of the

commemoratives so the orders received could be filled. Unfortunately, Mosser was

unable to run another 100, for their tanks had been cleaned and they were into

productions of other colors. They suggested that Robert Wetzel of Zanesville,

Ohio, be contacted to provide the additions to the run. Wetzel, a mould-maker by

trade, also had small glass furnaces, a press and cooling lehr behind his home.

He examined the samples run by Mosser and determined that he could duplicate

exactly what Mosser had produced... a white milkglass with a red transparent

glass swirling. In order to prove he could press the commemoratives, the mould

was transferred from Mosser to Wetzel's home. Wetzel pressed out five samples of

the commemorative in the glass that he was working in at the time. He mailed the

samples to the McDougalds. "We expected to see the white and red

combination, but instead they were a cobalt blue with milky white swirls,

relayed McDougald. Wetzel did fill the second run order of 100, but the units

never achieved the quality of red-swirling color that Mosser had produced. The

red transparent glass broke down into blue and yellow hues and didn't match the

color of those run at Mosser.

The selling price per commemorative was $14.00 in 1984. Much of the increase

reflected the use of a slag glass, which required two tanks of glass--- white

milkglass and red transparent. To watch the production was very interesting. One

gatherer placed red glass into the mould followed by a second gatherer's rod of

white milkglass. The insulator was pressed, but no swirling occurred. Five more

insulators were pressed this way. Since that was not the desired effect, the

order in which the glass was placed in the mould was changed.

White milkglass was placed in the mould first, followed by the red

transparent glass. They tried nine more samples, but it was not swirling. In

order to get the slag to work properly in the mould, a flotation collar, much

like a doughnut, was placed into the tank on top of the surface of the molten

white milkg1ass. A gathering rod was used to pull out a small quantity of the

red transparent glass which was dropped into the collar. The two colors were

then swirled together within the collar as it floated on top of the white

milkglass and then dropped as a pre-swirled gob of molten glass into the mould

to be pressed. About four slag glass commemorative insulators could be pressed

before more red glass was needed. No two insulators are alike when a slag glass

is used. A slag glass was also used in 1990, 1991, and 1993.

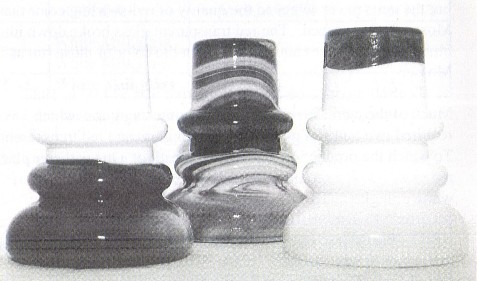

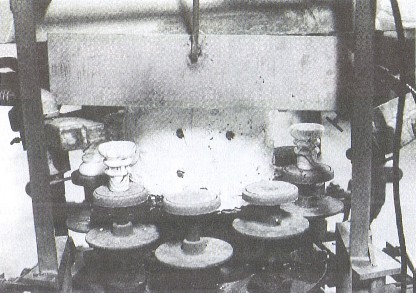

Cobalt with white milkglass swirls

sample sent by Wetzel Glass.

Two unsuccessful slag glass attempts flank the right combination.

1984 Commemorative Embossing:

15TH NIA CONVENTION

TACOMA, WASHINGTON JULY 20-22 1984

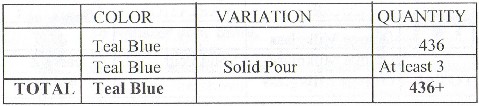

In 1985 a badly damaged CD 102 Diamond teal blue pony was matched for use in

the commemorative for the 16th national held in St. Charles, Illinois.

1985 Commemorative Embossing:

16TH NIA CONVENTION

ST. CHARLES, ILLINOIS JUNE 7-9 1985

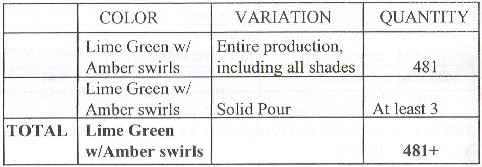

A sample of a Saratoga soda bottle was submitted (but not crushed) to match a

"green glass with amber swirls" for the 1986 national in Saratoga

Springs, New York. This was the first time that Mosser had tried to mix two

transparent glass colors. That should have been a warning sign right then. Amber

glass was gathered from its tank and placed in a flotation collar on the surface

of the green glass. The two colors were swirled together and dropped into the

mould. (In 1984 when white milkglass and transparent red were used there was a

major difference in glass density between the two colors, so the red color

swirled effectively in the dense white milkglass.) The amber and the green glass

in 1986 were too similar in nature to swirl. The two colors tended to blend

together and did not create the desired swirling. Many color variations, from

lime green to amber and everything in between, resulted from the production.

1986 Commemorative Embossing:

17TH NIA CONVENTION

SARATOGA SPRINGS, NY JULY 11-13, 1986

1987 Commemorative Embossing:

18TH NIA CONVENTION

FRESNO, CALIFORNIA JULY 24-26, 1987

A beautiful dark cornflower cordial glass was analyzed for the Houston

national in 1988 hoping that it would replicate the beautiful flower fields of

bluebonnets that are indigenous to that state.

1988 Commemorative Embossing:

19TH NIA CONVENTION

HOUSTON, TEXAS JULY 22-24, 1988

Dome Logo: Texas state outline and five point star for Houston

In all three cases of special-order colors, because of the greater thickness

of the glass in the commemorative and the instability of the glass mixtures, the

production color results were not what was anticipated by the show hosts or the

McDougalds. And, due to the fact that the colors were special order, absolutely

no guarantees are made by the glasshouse when new formulas and unproven recipes

are used. The commemoratives had to be taken "as produced." Finding a

new color each year continues to be a challenge, but past experiences dictate

that it is better to play it safe with the known than sorry with the unknown of

special requests for colors. In the last five years, there have been no

opportunities to select from previous colors manufactured. The colors used must

be on Mosser's production schedule.

Changes in the Mould

Since 1970, the national commemorative mould has undergone virtually no

changes except for the replacement of embossing rings. The plunger still

embosses an "FM" inside the top of the pinhole which honors Frank

Miller, its originator. With the number of new glass colors dwindling, an

attempt to bring some individuality to each year's run was begun in 1988. At

that time, a logo synonymous with the national show was embossed on the top of

the dome of each commemorative. You will remember that the top of the dome was

used for the location of the show embossings for the first two years in 1970 and

1971. When Frank Miller saw the 1988 commemorative with the outline of the state

of Texas and a "lone star" at the location of Houston, he said,

"Who was the genius that came up with finding a way to emboss the dome

again?!?" It seemed he had always liked the embossing on the top of the

insulator and was happy to see it was being used once again.

The variations in height of the commemoratives are caused by the erasure and

re-engraving of the embossing rings. Beginning in 1972, the bottom ring was

engraved to produce the embossing. At the end of each year's national show, the

following national show location is announced. As soon as the dates are

confirmed, the embossing ring is erased and re-engraved with the new show

information. This causes the depth of the glass at the bottom of the mold to

increase, making each insulator "grow in height" approximately .030

inches each year. This change in height is not discernible from year to year,

but readily noticed if comparing 1972 with 1984.

The first year dome embossing

was restored was in 1988.

The McDougalds received two base embossing rings from the Millers at the time

the mould transferred ownership. They were erased and re-engraved, alternating

the rings each year, until 1985. That year a new embossing ring had to be

ordered, and the overall height of the commemorative was reduced since the ring

was brand new. With both erasure and embossing occurring with the dome plate

necessary each year beginning in 1988, the growth in height continues on both

the dome and the base. Approximately four years of erasures/embossings are

gotten from the embossing plate and ring, so every fourth year the overall

height of the commemorative decreases. If you line up the complete set of

commemoratives, these changes are very apparent.

How Are The Commemoratives Made?

Production day at a glass plant is a fascinating process to watch. The day

before production, the cast iron mould is cleaned and oiled for operation.

Approximately ninety minutes prior to the beginning of the run, the mould and

plunger are placed into the lehr and slowly heated to a temperature of

approximately 1000 degrees Fahrenheit.

Also mixed the day before the run are 2000 pounds of sand, soda ash, potash,

lime, hydrated aluminum and other ingredients and coloring agents specific to

the recipe called for to produce a given color product. Some batches also

include crushed cullet (glass of the same color from poorly molded pieces broken

and saved from a earlier run).

The BATCH is placed into the DAY TANK and melted for use in the production

run the next day. Its temperature needs to reach 2600 degrees Fahrenheit by the

time production begins. Once the heated mould is positioned on the press,

production is ready to begin.

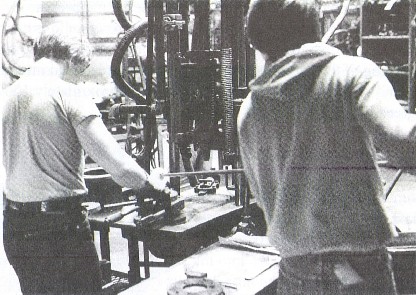

The GATHERER uses a long rod, called a punty hook, to remove molten glass

from the day tank. A slow twirling motion of the punty hook gathers the right

amount of molten glass on the end of the rod. The gatherer then moves the punty

hook loaded with molten glass towards the waiting, heated mould. The molten

glass drops to a temperature of 1950 degrees Fahrenheit by the time it reaches

the mould.

The gatherer holds the molten glass over the mould. Gravity takes over, and

the molten glass begins to drop towards the waiting mould. The PRESSER takes

shears in his right hand and cuts off the correct amount of molten glass from

the punty hook and lets it drop into the closed mould.

With his left hand, the presser takes the embossing ring from a hot plate and

places it upside-down on top of the closed mould, so the embossing is facing the

molten glass inside the mould. With the mould secured and the embossing ring in

place, the presser pulls on the lever with both hands to lower the plunger into

the mould. The plunger displaces the molten glass inside the mould and pushes it

upwards against the embossing ring. The plunger, which contains the engraved

initials "FM" (for "Frank Miller"), embosses the top inside

of the commemorative's pinhole.

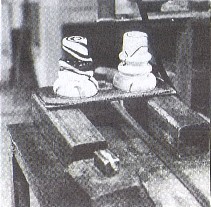

The gatherer brings molten glass to the mould where

the presser shears off the correct amount to press.

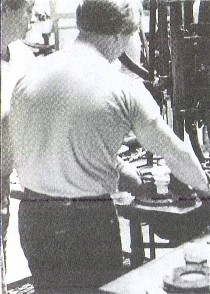

The plunger is then raised, the embossing ring removed and the mould

reopened. The TURNING-OUT BOY uses tongs to remove the red hot commemorative

from the mould. It is also his job to examine the insulator for readily

discernible flaws--poor embossing, stones, cracks, and other imperfections.

Defective pieces are immediately placed in a large cart filled with water. As

imperfect units hit the water, they immediately shatter internally, making them

easily readied to become cullet for another run of the same color.

Preparing to remove the pressed

insulator from the mould.

Perfect units rest momentarily on an asbestos screening. Two hot AIR JETS

begin cooling the insulator. The turning-out boy then places the good

commemoratives onto a GLAZING WHEEL. The wheel is similar to a carousel which

has 16 rotating pallets that continuously turn each insulator, exposing its

surfaces to flame jets which polish the glass and remove any imperfections such

as excess glass that might have oozed through seams between the mould and

embossing ring.

Air jets begin cooling process.

Should a carnivalization or similar surface coloring treatment

be desired, it would be applied directly to the insulator prior to it being

fired on the glazing wheel. The "carousel ride" for each insulator

takes about one minute.

The GLAZER MAN removes the insulators from the glazing wheel and

places them on a long-handled metal spatula -- just big enough to carry two

insulators. The temperature of the glass is now approximately 1000 degrees

Fahrenheit.

Two by two, the commemoratives are carried by the glazer man to

the LEHR. This is a 75 to 100 foot long heavy wire mesh belt which

"rides" through a cool-down oven. The temperature at the press room

end is 1000 degrees Fahrenheit. The other end of the lehr delivers a cooled

insulator to the final INSULATOR GLASS PACKER. The glass is cooled to 100

degrees Fahrenheit by the time it reaches the packing room. Glass factories can

regulate the speed of the belts running through the lehrs. It is very possible

that another product can be cooling on a second track which may require a longer

or shorter ride in order to anneal the glass properly.

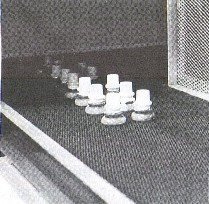

The annealed commemoratives

approach the end of the cooling lehr

and emerge into the room for packing.

|